![]()

China intends to hold onto its title as the ‘world’s factory’ while rebranding itself internationally as an exporter of sophisticated products rather than cheap ones.

China has ambitious goals for its export market and the reputation surrounding it, recently launching the ‘Made in China 2025’ policy initiative. Beijing plans develop the country’s hi-tech capabilities to put it on the same playing field as manufacturing powerhouses Germany and Japan.

In the next 10 years, the policy is designed to move Chinese manufacturers further along the value chain, to promote investment in research and development, encourage Chinese companies to build global brands and implement environmentally sustainable practices.

It’s a reaction to pressure coming from two sides — developing countries with lower labour costs which can now produce things more cheaply than China and developed nations with more efficient manufacturing technologies.

‘Made in China 2025’ has been compared to Germany’s ‘Industry 4.0’ strategy which envisages manufacturing taking place within a ‘Smart Factory’ powered by digital processes. The Siemens factory in Germany is a shining example of the concept. In February this year, German Chancellor Angela Merkel visited the factory in Amberg, Bavaria to inspect the process whereby production is largely automated. Machines and computers are responsible for 75 per cent of the value chain, and employees handle the rest.

German Chancellor Angela Merkel visits the Siemens factory in Bavaria.

Siemens describes their factory of the future as: “Products finding their way independently through the production process. In intelligent factories, machines and products communicate with each other, cooperatively driving production.”

Apart from lower labour costs, another benefit of these factories is the ability to adapt to shorter product life cycles. Shorter life cycles mean manufacturing will have to become more agile to deliver mass produced products to market as quickly as possible.

Recently CEO of Haier Group Zhang Ruimin said the Chinese whitegoods company and parent company to Fisher & Paykel, would need to transform its business, shifting to advanced manufacturing in a wireless age.

“We used to think: maximise quantity, export more and manufacture more. This isn’t working,” Zhang told Reuters.

One of the outcomes of Haier’s smart factories will be the ability to mass produce customised appliances that can be ordered online. Reportedly, Haier is developing an app that will allow customers to watch their products being made on a live video feed.

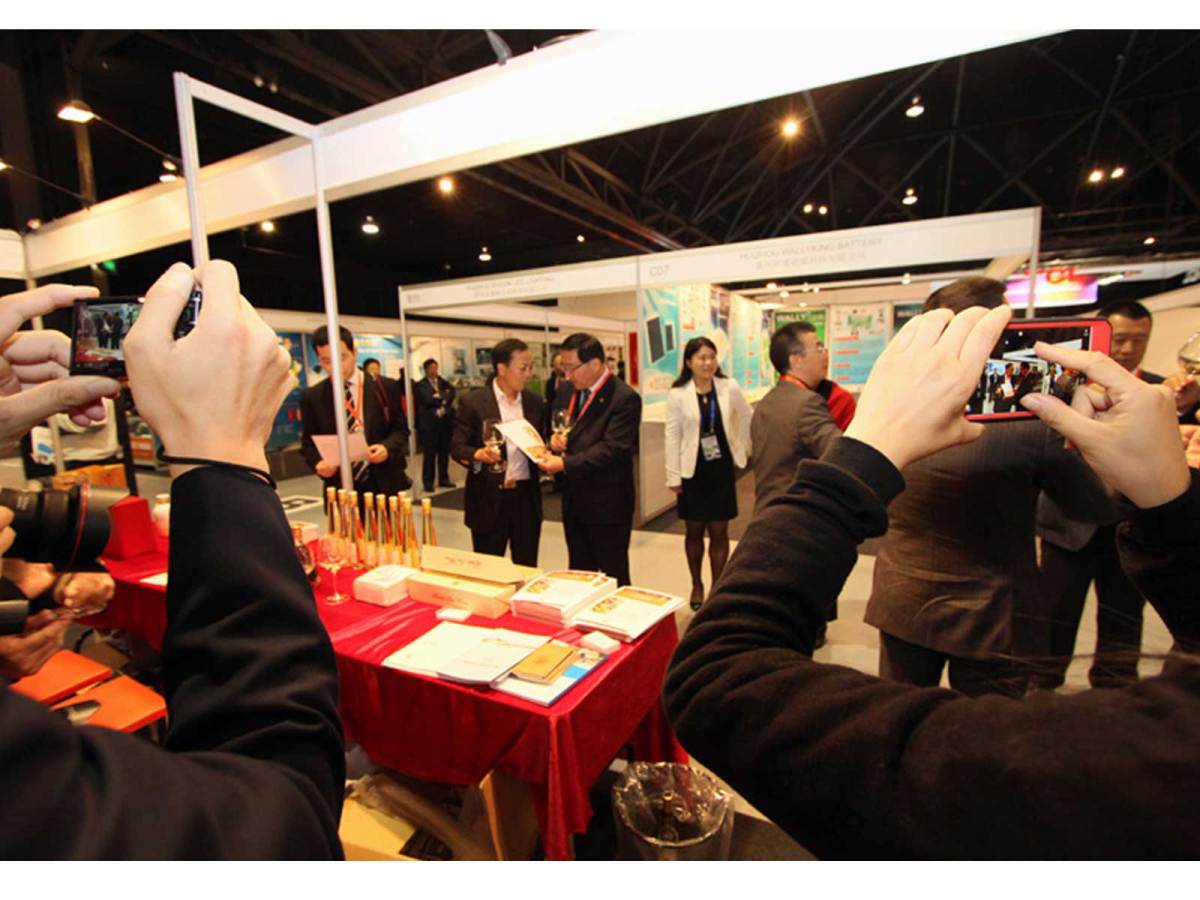

This shift in approach to Chinese manufacturing was a hot topic of discussion last week at the Huizhou Products Expo in Sydney. The Expo, held in Sydney’s Hordern Pavilion, was part of a wider trade delegation which was the biggest to visit Australia since the signing of the declaration of intent for the China Australia Free Trade Agreement (ChAFTA). The declaration of intent formalised the terms of the free trade agreement between the two countries on 17 November 2015.

TV manufacturer TCL is from the Huizhou region and was the star of the Expo with a prominent position at the front of the exhibition, promoting a successful 10 years in the Australian market. It was also previewing its new curved, Ultra HD televisions that come with an RRP far below its competitors.

Huizhou is known for its consumer electronics manufacturing and is home to a ready workforce equipped with skills to manufacture LED screens. It has a population of 5 million and is located just outside the capital of Guangdong Province, Guangzhou.

Also exhibiting at the show was household appliances company Desay, which is a Huizhou company with international provenance. Desay began as a joint venture with Dutch brand Philips producing car audio equipment, electronics and dashboard components. The Dutch contingent exited, and Desay then partnered with German brand Siemens. In 2010 Desay’s management bought out all Siemens’ shares. Today it employs more than 20,000 people and manufacturers LED screens and automotive components, as well as home appliances.

These kinds of global connections between Western and Chinese companies was also apparent at the 2015 Hong Kong Electronics Fair (Spring Edition) held in April. Walking through the exhibition hall, German, Spanish, Australian and American accents could be heard describing their wares; ideas conceived abroad but engineered and manufactured in China.

More and more hardware start-ups from around the world are relocating operations to Shenzhen, a manufacturing mecca located in Guangdong Province just north of Hong Kong. It’s a move that’s seen as critical to be able to bring the best product to market on mass as it puts the entrepreneurs in touch directly with experts in electronics componentry.

If international collaboration and hi-tech manufacturing enshrined in ‘Made is China 2025’ are successful then Australia is well positioned to benefit, with Chinese delegations keen to deal with Australian buyers.

“Since the announcement of the China Australia Free Trade Agreement, Chinese interest in doing business with Australia has increased enormously,” said Huizhou Products Expo director Cindy Xin.

“Chinese companies view Australia as an important market because there is great cooperation at government level between the two nations; but also because Australia is viewed as a very strong market in which Chinese producers develop their brands to suit a western audience.

“The exhibitors at the Huizhou Products Expo are all looking for long-term relationships in Australia and are willing to negotiate excellent terms with customers,” she said.

Johnson Shi, deputy director of the Huizhou Municipal Bureau of Commerce, told Appliance Retailer that there are around 350 manufacturers based in Huizhou that are already in various stages of doing business with Australia. With the free trade agreement definitely on the cards, now is a good time to jump in and get familiar Australia, he said, “so when the door is really open we are ready.”

“Sydney is attractive to us because, first of all we view Sydney as not only a major city in Australia but rather as the centre of the southern hemisphere. On top of the large population the city has already, it is the centre, it can really drive business here.”

Sydney’s tourism, sound business environment with good governance, and its reputation as safe, friendly and culturally tolerant are all important factors for Chinese exporters looking for trading partners, Shi said. Harbour views and a mild climate don’t hurt the city’s trading credentials either.

“In business you have to travel a lot, but when you have a choice you’d rather travel to a pleasant destination!”